The Mk12 and The OPS Inc / AEM5 Suppressor Evolution

Posted by Charlie's Custom Clones Staff on Oct 11th 2024

The Mk12 and The OPS Inc / AEM5 Suppressor Evolution

Introduction

The world of firearms has seen many trends over the past quarter-century, but few have been as significant as the rise of suppressors. Among these, the OPS Inc #12 suppressor stands out as a pivotal development in both engineering and military applications.

This blog delves into the rich history of OPS Inc, its transition to Allen Engineering, and the subsequent developments that have shaped the modern suppressor market. Let's explore the origins of these innovative designs, their adoption by elite military units, and their enduring legacy in both military and civilian circles. From the visionary work of Phil Seberger to the precision craftsmanship of Ron Allen, and the rise of new faces, this article provides a look at a fascinating chapter in firearms history.

And, chances are you did not know just how cutting edge the OPS, Inc. suppressors were for their time. We take so much for granted today about suppressors, but before GWOT, OPS, Inc. was the gold standard of suppressed fire. Today, only us clone nerds even recognize the name. Before Silencerco, before Dead Air, before Surefire, OPS Inc was the bees knees.

And this rich military history still comes alive with Allen Engineering and the Mk12 rifle. An you can experience history - the best way - by shooting it !!!

Table of Contents

- The Evolution of Suppressor Design Techniques

- Innovations in Sound Wave Manipulation

- Seberger's Suppressor Revolution

- Allen's Precision Revolution

- Military Suppression Adoption

- OPS Inc #12 Sniper Rifle Adoption

- Allen Engineering Ascendance

- OCM5: Opportunistic Clone Emergence

- Allen's Manufacturing Transition to Utah

- OPS Inc Design Legacy

- New Metals and Flow-Through Suppressor Revolution

- Authenticity Spectrum in Cloning

- Legacy of OPS Inc Innovation

Picture credit: Military Times

The Evolution of Suppressor Design Techniques

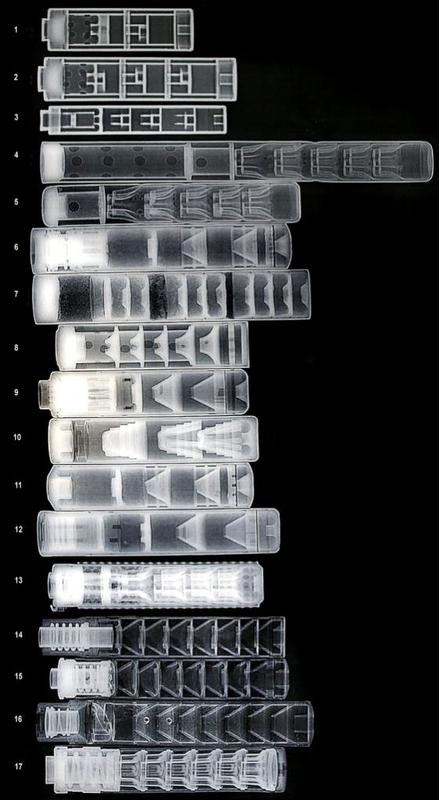

The evolution of suppressor design techniques has seen significant advancements since the early 20th century. Initially, suppressors relied on simple baffle designs to trap and slow expanding gases. However, modern approaches employ sophisticated engineering principles to achieve superior noise reduction.

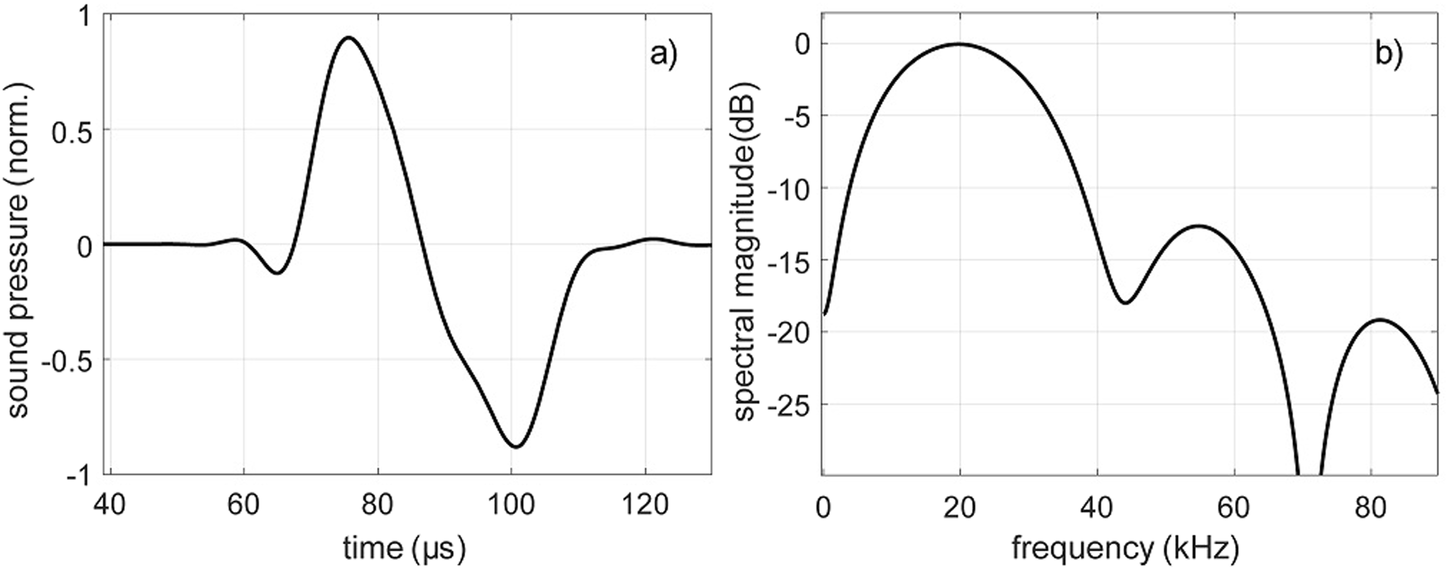

Phil Seberger's innovative technique in the late 1970s utilized sensitive microphones and oscilloscopes to visualize high-frequency sound waves, enabling precise tuning of baffle designs. This method allowed for the development of suppressors that work by capturing and redirecting sound waves to cancel each other out, similar to noise-cancelling headphones.

Seberger worked on the esoteric nuances of sound and its effect inside a rifle, like had never been seriously evaluated before. While a lot has changed in suppressor technology since his early research in the 1970's and 80's, his work with frequency shifting and phase cancellation, which aimed to shift audible frequencies into the ultrasound range or create destructive interference was ground-breaking at the time.

Innovations in Sound Wave Manipulation

Advancements in sound wave manipulation have made a lasting mark on suppressor design and acoustic control. Researchers have developed techniques to precisely shape and redirect sound waves using computational methods and novel materials.

For example, a team led by Changxi Zheng created "acoustic voxels" - small primitives that can be rapidly modified to change acoustic characteristics of air chambers.

This allows for customized acoustic properties in objects like wind instruments and industrial mufflers.

Another breakthrough is the use of plasma (ionized air) to manipulate sound without traditional acoustic materials. Researchers demonstrated an ultrathin plasmacoustic metalayer capable of achieving over 95% sound absorption across a broad frequency range (20 Hz to 2 kHz). This breaks the conventional "quarter-wavelength rule" limitation.

Seberger's Suppressor Revolution

OPS Inc, founded in 1988 by Phil Seberger, revolutionized suppressor design through innovative techniques and a focus on military applications. Seberger, an electrical engineering genius, developed a method to precisely measure and visualize sound waves of suppressed rifles using sensitive microphones and oscilloscopes.

Unlike traditional suppressors that slowed or trapped gases, OPS Inc designs captured and redirected sound waves, causing them to cancel each other out - similar to modern noise-cancelling technology.

"I got the bright idea that if I could go and hold the first sound pulse back in time, and insert it back when the second pulse came along, I’d have sound cancellation and I’d have nothing left but heat... “For Example: if two billiard balls are rolling towards each other at the same speed, once they collide, the energy will cancel itself out and stop the two balls.” Phil Seberger, July 2000 Guns Magazine.

This approach impressed U.S. Army engineers at Aberdeen Proving Grounds, opening doors for military contracts. Seberger's vision of providing cutting-edge suppressor technology to the U.S. Military led to the development of highly effective designs like the OPS Inc #12, which became a pivotal component of the Mk12 Special Purpose Rifle.

The company's focus on military sales over civilian markets initially limited its commercial reach, but laid the groundwork for a lasting impact on suppressor technology and military operations.

“For Example: if two billiard balls are rolling towards each other at the same speed, once they collide, the energy will cancel itself out and stop the two balls.”

Allen's Precision Revolution

In 1993, the trajectory of OPS Inc took a significant turn when Ron Allen, a skilled machinist making semiconductor parts for Silicon Valley companies, received an unexpected call from Phil Seberger. Seberger was seeking someone with true machinist skills to manufacture precision components like muzzle brakes for OPS Inc suppressors.

Initially skeptical, Allen soon found himself partnering with Seberger, bringing modern machining techniques to complement Seberger's innovative designs. Allen recalled, "Phil was a genius and an amazing electrical engineer. But some of his self-taught machining techniques would make me cringe.”

This partnership marked a crucial evolution for OPS Inc, combining Seberger's visionary suppressor concepts with Allen's manufacturing expertise.

Allen made significant improvements to the production process upon joining Seberger. These refinements elevated OPS Inc suppressors from brilliant concepts to precisely engineered, highly effective products that would soon see extensive military use.

Allen's process and design improvements included creating a new single-piece first section that improved consistency and manufacturability. He also added a 20-degree flange in the collar and suppressor end to create a better gas seal and more repeatable zero when removing and reinstalling the suppressor.

Allen led the manufacturing for OPS Inc. for 10 years, from his start in 1993 through Seberger's death in 2010, and continuing to the close of OPS Inc. in 2013.

"Phil was a genius and an amazing electrical engineer. But some of his self-taught machining techniques would make me cringe."

Military Suppressor Adoption

It was in the late 1980's that Seberger worked with the US Army to position the M24A2 Sniper Weapon System with a suppressor. In 1986, the Army chose the OPS Inc 3rd Model. The existing M24's would be re-barreled starting in 1988 to accept a profile for the over-the-barrel suppressor design and be put back into the field with the added Picatinny rail system for night vision illuminators.

It was in the late 1980's that Seberger worked with the US Army to position the M24A2 Sniper Weapon System with a suppressor. In 1986, the Army chose the OPS Inc 3rd Model. The existing M24's would be re-barreled starting in 1988 to accept a profile for the over-the-barrel suppressor design and be put back into the field with the added Picatinny rail system for night vision illuminators.

It is hard to imagine it now, but OPS Inc was the gorilla in the room when it came to silencers at the time. The names you think about today did not exist until more than a decade later, and many got their inspiration from Seberger's design.

Kevin Brittinham had not yet founded AAC. Knights Armament had yet to build an SR25 or think about a suppressor. When they did, their first suppressor was the Mk11, which was an over-the-barrel design like Seberger's. The Mk11 found its way onto the Navy's sniper rifles: The Mk11 and the Mk13. The other names you might think of: not yet in business, and will not be for 15+ years.

Surefire was busy making flashlights: Barry Dueck, who would later found its suppressor division in 2002, was a former Marine and working at the time with Seberger doing research and development.

Said Duek in a 2002 interview, "...he [Seberger] wants the operators to have the best."

Throughout the 1990s, OPS Inc continued to provide M24 sniper rifles with silencers, and began offering an even more popular model that fit on M16 based weapons.

In addition, Seberger and his team developed a number of one-off suppressors when called upon by Special Forces operators, like the one used by Medal of Honor recipient Master Sergeant Gary Gordon during Operation Gothic Serpent during the battle of Mogadishu. Today, the Gordon Carbine, made popular by the movie, Black Hawk Down, is a favorite of military clone rifle enthusiasts. Even in recreating this historic suppressor, a fair amount of research had to go into it, as there were few surviving models of what was build for the special operators at the time.

"Seberger wants the operators to have the best."

OPS #12 Sniper Rifle Adoption

The OPS Inc #12 suppressor was developed specifically for the Mk12 Special Purpose Rifle (SPR) in the late 1990s. Building upon the momentum of the M24 and the now proven track record of OPS Inc silencers in action with the US Army, the Navy planners at NSWC Crane and the US SOCOM quality panel chose a new model, the 12th Model from OPS Inc to serve as its suppressor for the new 5.56mm gas sniper rifle.

This marked a significant advancement in military suppressor technology. the key features of the OPS Inc #12 included fusion welded 300 series stainless steel tube and Seberger's noise-cancelling configuration of baffles. The design met the SOPMOD objective of 30,000 rounds endurance under various firing schedules.

The #12 model's over-barrel design added only 4.5 inches to the muzzle length, despite its 8.8-inch overall length. This minimized the rifle's length, while providing excellent sound suppression. The suppressor attached via a muzzle brake and an adapter collar, allowing for use with or without the suppressor.

As part of the original Mk12 SPR in 2000, the OPS Inc #12 saw widespread use in the Global War on Terror. Its performance in combat situations cemented its reputation as one of the most effective suppressors of its time.

The success of the #12 suppressor on the Mk12 platform, led to increased demand, particularly among special operations units, and played a crucial role in establishing OPS Inc as a leading supplier of military-grade suppressors for the GWOT.

Allen Engineering's Ascendance

Following the close of OPS Inc in 2013, Ron Allen continued the Seberger legacy with Allen Engineering building pretty much the same suppressors that Allen built during his time at OPS Inc.

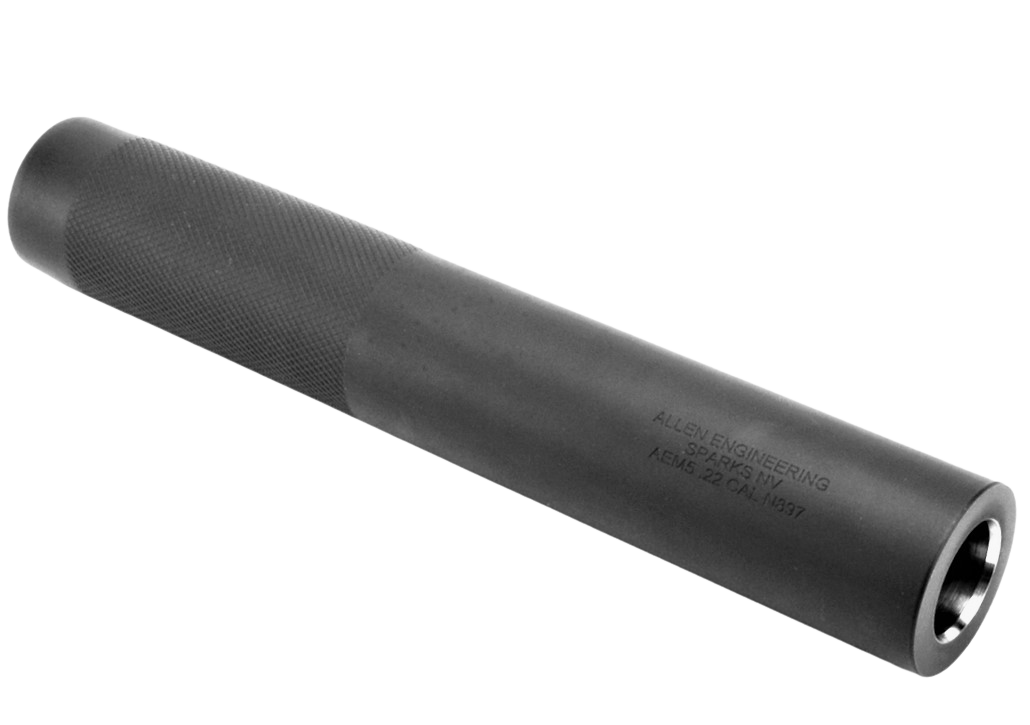

The AEM5 suppressor, developed by Allen as the successor to the OPS Inc #12, quickly gained traction in both military and civilian markets. Its design maintained the core principles of the OPS Inc #12 while incorporating minor refinements based on Ron Allen's extensive manufacturing experience.

The AEM5 became particularly popular among enthusiasts seeking to replicate the Mk12 Special Purpose Rifle (SPR) configuration.

From 2013 onwards, Allen Engineering saw steady production of the AEM5, along with other former OPS Inc designs. The company supplied suppressors, collars, and brakes to various dealers and manufacturers, including Precision Reflex Inc. (PRI) for their near-clone Mk12 Mod 0 and Mod Holland rifles. The AEM5's popularity extended beyond the Mk12 platform, with many enthusiasts adopting it for other builds like the Navy's RECCE rifle.

There was an ongoing demand for legacy suppressors for military clone rifles. The Mk12 rifle, was a favorite of clone enthusiasts. Not only was it authentic, but it was a good shooter. Allen Engineering continued to get a steady flow of customers.

The AEM5 for the Mk12 SPR was the bulk of his orders, along with custom made brakes and collars. But, Ron would also build a variety of AEM suppressors, and one day, we will have to explore each of those. This author will need Ron to spend a few minutes explaining. Ron did not take the easy route in naming. The #12 became the #5, and the #3 became the M24, and the #3 was something shorter. Engineers and machinist stand out from marketing types. LOL.

The AEM5's success can be attributed to several factors:

- Military pedigree: Its lineage from the combat-proven OPS Inc #12 design.

- Performance: Excellent sound suppression and minimal impact on weapon handling.

- Authenticity: Crucial for clone builders seeking historically accurate reproductions.

- Versatility: Adaptable to various AR-15 platform rifles beyond the Mk12.

As time went on, from roughly 2016 into 2018, the pace of demand for Allen suppressors was growing steadily each year. Ron had a limited output, but business was good. By 2000 the demand was biting at Allen's ability to produce. He started to get a backlog, and started to work harder and longer hours.

Going into 2021, it seemed that the added work might be wearing on Ron. Deep down, he was a tinkerer. He started to look for perhaps someone to take on some of the production work, so he would spend time on one-off projects. Ron seemed to very much enjoy taking the call of a shooter or clone guy to build that special suppressor or odd measurement for a collar, or a protoyype of something new and fun.

Demand for the AEM5 had now outpaced Allen Engineering's production capacity, leading to extended wait times and creating an opportunity for alternative manufacturers to enter the market.

This surge in popularity solidified the AEM5's status as a benchmark in the suppressor industry, influencing both military and civilian suppressor designs for years to come.

OCM5: Opportunistic Clone Emergence

Otter Creek Labs (OCL) entered the clone rifle suppressor market with the OCM5 at a time of heighten demand, and limited supply.

The OCM5 was designed as a direct copy of the Allen Engineering AEM5. Otter Creek’s opportunistic response, seized upon Allen's production limitations and the backlog of orders for a Mk12 suppressor in 2021.

Andrew King, OCL's founder, leveraged his experience from the Form 1 suppressor community to grow into a suppressor business.

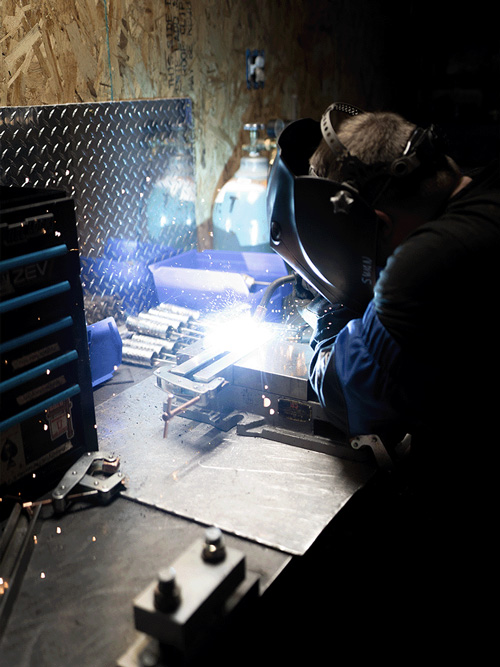

While visually similar to the AEM5, the OCM5's internal design diverged from Seberger's original noise-cancelling principles. King employed manufacturing methods that fit his Form 1 background and leveraged his welding training and limited early production equipment.

King also opted to use a different material for his suppressor, resulting in a lighter can while maintaining compatibility with existing Mk12 components from Allen Engineering.

The facts may be important to some, and unimportant to others, but King's venture into the world of clone rifles and the design of the OCM5 was without any collaboration with Ron Allen. He copied the AEM5, and he has said he made it better. Maybe. The design was off-patent, so he can do as he pleases. There have been accounts written that suggested that King and Allen collaborated, or that King make the copy with Allen's permission. That is not so.

The OCM5 quickly gained traction among dealers and enthusiasts. Charlie's Custom Clones, a leading seller of Mk12 rifles and components, became an early adopter of the OCM5, offering it as an alternative to customers facing long wait times for Allen Engineering suppressors.

While not a direct replacement for the original OPS Inc 12th model or AEM5, the OCM5 provided a viable solution for those seeking to complete their Mk12 builds. It filled a gap.

Video credit to Joe Lynch: @joesrcool

From a distance, on or off a rifle, there was no visual difference between the Allen original and the Otter Creek replica, and the new clone model fit all of Allen’s barrel hardware. Using titanium instead of stainless steel, Otter Creek and thus achieved a 19% weight reduction over the Allen suppressor design, and performed as well in sound testing. King claimed it was a tad bit quieter.

The OCM5's introduction highlighted the ongoing tension between historical accuracy and practical considerations in the military clone rifle community. While purists may prefer the original Allen Engineering products, the OCM5 offered a more readily available alternative that closely mimicked the look and function of the AEM5.

Allen's Manufacturing Transition to Utah

After ceding some market in the clone suppressor space to an unauthorized manufacturer, Ron Allen bounced back and doubled-down on production of the AEM5 in 2022 by establishing a second productions facility for Allen Engineering products in Utah.

In late 2022, a significant development occurred in the production of Allen Engineering suppressors. Roughly a year after Otter Creek started to make the Allen look-alike cans, Ron entered into a binding Engineering with Alex Bohl of Trajectory Arms, now also operating as Allen Engineering of Orem, Utah. This collaboration aimed to ensure the continued production and availability of authentic Allen Engineering suppressors, particularly the AEM5 and M4 Gordon models.

Under this arrangement, Trajectory has taken on the primary manufacturing role for the majority of AEM5 and M4 Gordon suppressors. Crucially, Alex and his team at Trajectory adhere to the same materials and manufacturing methods that Ron has used for years, maintaining the suppressors' authenticity and quality.

Take from an article by Daniel Y. in The Firearms Blog, October 22, 2022:

"Alex stressed that this is not a clone or imitation. It is a real AEM5, made from the original drawings. He showed me some of those drawings and they are absolutely the real deal from the 1980s. The only difference between a Trajectory-made can and the original is the manufacturer’s location marking."

"Ron Allen is still very involved in the Allen Engineering project. In fact, he called Alex while I was visiting the shop. The AEM5 is, by far, the most popular Allen silencer."

Ron Allen is now concluding some outstanding orders to some larger dealers. He also maintains production of most of the brakes and one-part Mk12 SPR collars. The three-part Gordon collars are now manufactured by both Ron Allen and Alex. Ron looks forward to the not so distant future when Alex will have the full burden of Allen Engineering, and he and his bride, Cheryl can fully retire.

The Trajectory Arms partnership demonstrates the ongoing evolution of the suppressor market, balancing the preservation of historical designs with the need to meet growing demand and potentially introduce new innovations in suppressor technology.

"This is not a clone or imitation... It is a real AEM5, the real deal...

Ron Allen is still very involved...."

OPS Inc Design Legacy

The legacy of OPS Inc designs continues to exert a profound influence on the suppressor market.

Seberger was a pioneer. Both in terms of suppressor design, and also in his development of the military market for suppressed sniper rifles. Other leading names in the suppressor industry followed in his footsteps.

He set benchmarks for performance and reliability. He revolutionized military suppressor technology with its innovative sound wave manipulation techniques and over-barrel design.

The OPS Inc #12 suppressor, developed for the Mk12 Special Purpose Rifle, and earlier the M24 suppressor made an impact on how sniper rifles were designed and deployed with noise suppression. This legacy lives on through Allen Engineering's continued production and refinement of these iconic suppressors.

The OPS Inc #12 suppressor, developed for the Mk12 Special Purpose Rifle, and earlier the M24 suppressor made an impact on how sniper rifles were designed and deployed with noise suppression. This legacy lives on through Allen Engineering's continued production and refinement of these iconic suppressors.

Ron Allen's dedication to quality and customer service has ensured the enduring popularity of these designs. The recent partnership with Trajectory Arms has further solidified the future of Allen Engineering suppressors, maintaining production capacity and authenticity while opening doors for innovation and further design refinements.

This collaboration ensures that the AEM5 and M4 Gordon suppressors continue to be manufactured using the same materials and methods that have made them highly sought after by enthusiasts and professionals alike.

photo credit: Sgt Pete Thibodeau, US Department of Defense

Looking ahead, the Allen team has hinted at the development of a .300 BLK suppressor, demonstrating their commitment to expanding their product line while maintaining their core design principles. As Ron Allen explained, "The baffle design has to be optimized for the larger subsonic rounds," highlighting the ongoing research and development efforts.

The influence of OPS Inc designs extends beyond direct production. Early military designs from Knights Armament, Surefire and ACC showed that designs would evolve beyond the early tooling doing by Phil Seberger. And even very recent designs from Griffin Armament showcase the improved computerized design refinements on an older design of a reflux can.

Alternatives like the Otter Creek Labs replica suppressor showcase how different materials and manufacturing methods can be employed to offer lighter weight options that closely mimic the look and performance of the original designs. This evolution in the market demonstrates the lasting impact of OPS Inc's

As the suppressor market continues to evolve, with advancements in materials science and manufacturing techniques, the principles established by OPS Inc and refined by Allen Engineering remain a touchstone for quality and performance. The legacy of these designs serves as a benchmark.

New Metals and Flow-Through Suppressor Revolution

This trend is likely to continue as manufacturers strive to meet the diverse needs of military, law enforcement, and civilian users while pushing the boundaries of suppressor performance and versatility.

While the AEM5 remains popular among clone rifle purists, newer options offer lighter weight and more easily produced alternatives that closely mimic the aesthetics and performance of the original 12th Model suppressors.

Other OPS Inc inspired designs offer significant innovations from other manufacturers. Griffin Armament has introduced near-alternatives to Knights sniper rifles, while Knights Armament itself has recently developed a reduced back-pressure NT4 style suppressor.

Companies like CGS and HUXWRX are pushing the boundaries of suppressor technology with sintered stainless and titanium 3D-printed suppressors, as well as flow-through designs that represent a significant departure from traditional baffle systems.

Other manufacturers are using Inconel, Titanium and other alloys that are used on rockets. Sintered metals can now be combined in additive manufacturing.

These modern alternatives often incorporate advanced materials and manufacturing processes to achieve improved performance characteristics. For example, the use of titanium in suppressors allows for weight reduction without compromising durability.

Additionally, 3D printing technologies enable the creation of complex internal geometries that were previously impossible or impractical to manufacture, potentially leading to more effective sound suppression and reduced gas blowback.

The rise of these modern alternatives reflects the ongoing evolution of suppressor technology, balancing the preservation of proven designs with the incorporation of cutting-edge materials and manufacturing techniques.

This trend is likely to continue as manufacturers strive to meet the diverse needs of military, law enforcement, and civilian users while pushing the boundaries of suppressor performance and versatility.

Authenticity Spectrum in Cloning

In the world of military rifle enthusiasts, the distinction between "clone-correct" and "near-clone" builds is crucial. Clone-correct builds aim for exact replication of military firearms using period-correct components, demanding extensive research, sourcing of rare parts, and attention to minute details like correct markings and finishes. This approach often results in costly but historically accurate reproductions.

Both the clone-correct and near-clone approaches contribute to preserving these iconic firearms' legacy, with clone-correct builds serving as precise historical records and near-clone configurations broadening interest and accessibility within the enthusiast community. This is true whether military clone rifle enthusiasts are building their own, buy a full rifle or upper receiver, or sourcing larger components from commercially available sources.

The legacy of OPS Inc and Allen Engineering suppressors represents a pivotal chapter in firearms history, blending innovation, precision engineering, and real-world combat effectiveness. From Phil Seberger's groundbreaking designs to Ron Allen's manufacturing expertise, these suppressors have set benchmarks for performance and reliability in both military and civilian sectors.

The OPS Inc #12 and its successors revolutionized suppressor technology through innovative sound wave manipulation techniques and over-barrel designs.

This legacy continues to influence modern suppressor development, as evidenced by the ongoing production of Allen Engineering suppressors and the emergence of inspired designs from Surefire and Knights Armament. The recent partnership between Allen Engineering and Trajectory Arms ensures the continued availability of these iconic suppressors while potentially opening doors for future innovations.

As the suppressor market evolves, with advancements in materials science and manufacturing techniques, the principles established by OPS Inc and refined by Allen Engineering remain a touchstone for quality and performance.

The tension between preserving historical designs and incorporating cutting-edge technologies is exemplified in the debate between clone-correct and near-clone builds, reflecting the broader challenges and opportunities in the firearms industry.

Ultimately, the story of these suppressors transcends mere technical specifications. They have become integral to American military and shooting culture, inspiring new generations of enthusiasts, engineers, and manufacturers. As the industry continues to innovate, the legacy of OPS Inc and Allen Engineering stands as a testament to American ingenuity and the enduring pursuit of excellence in firearms technology.

Sources and Recognition

- Shout out to Brian Sanders and his research at Trajectory Arms .

- Credits that I could not write to The Firearms Blog for pics with the logo, and several good articles, one is cited in the blog.

- Thanks to Ron Allen for the many long stories, which spired the article. There is one unattributed quote, which came from the Seberger interview of 2000.

- DOD for several great pics.

- A few anonymous pics that I could not figure out where they came from, so if it is yours, let me know.

- To a handful of industry guys, from whom had a lot to offer in snippets

- Video credit to Joe Lynch and Mission Ridge.

- Direct quotes are given sources.

- Direct conversations and background information from Jay at Pew Science, Alex at Trajectory, Bobby at CGS Group, Austin at Griffin Armament, John and Andrew at Otter Creek Labs and Josh at AAC