Douglas Barrels

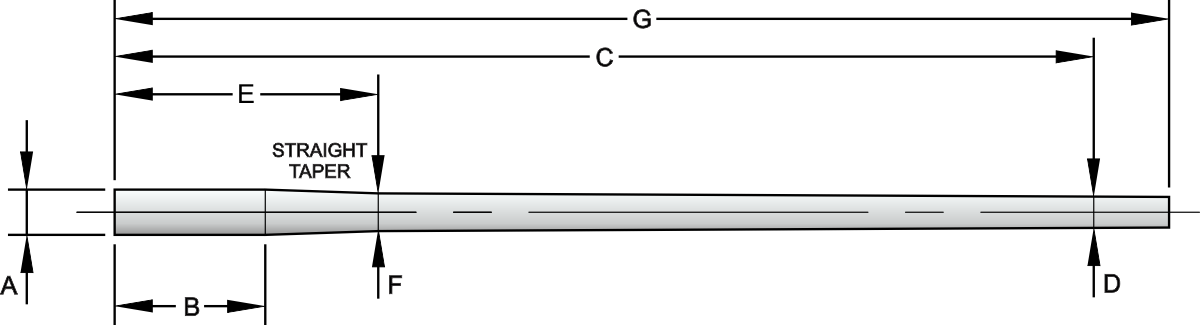

This is the military correct barrel for an M40 rifle build, to be chambered and installed by a gunsmith. The blank comes delivered at 28." The final product is 25" and then the final inch is screwed into the Remington 700 Short Action for an overall final length of 24". The barrel has a straight taper, from 1.21" with a 3" full width throat, and then a straight taper to 0.89" at 26.5" and continuing straight to 28."

At Charlie's, we are barrel snobs. The Schneider barrel has won a number of long range precision matches. It is a very good barrel and handcrafted to create a very accurate barrel, which is known well by the long range shooting community, as well as M40 sniper rifle military clone builders and gunsmiths. This is the barrel you want for your M40 build. At the price, you can find another barrel, which will be almost as good, and perhaps shoot just as well, but you will be saving maybe $100 or $200, and you will not get the real barrel used by USMC snipers. That is why you want a Schneider barrel for your M40. Charlie's is trying to keep these in stock, as well as other components, mostly for M40A3 and M40A5 builds, but this barrel will work fine for all M40 builds. Can you order direct from Schneider? Of course, you can. You will get the same barrel, for roughly the same price, and wait a great many months. Charlie's will cost you a small amount more than ordering from Schneider, but we are ordering every quarter, and hope to have in-stock, and if not in-stock, you can sign up to be notified, as we will have barrels on order and arrive soon.

Schneider barrels are made from match grade stainless steel, and rifling is done with a pull button process, which involves pulling a carbide button to create the 6 grooves in an M40 barrel. This button is larger than the reamed hole and therefore displaces steel to form the groves and lands of the rifling. This process results in a very uniform surface that is hardened as a consequence of the compression of the steel and "work hardening".

The helix for the desired twist-rate is ground into the button to match the desired twist rate of the finished barrel. The button-pulling mechanism is set to match the helix of the button to provide precise twist-rate uniformity. Thereafter, the barrels are stress-relieved according to a specific time and temperature profile, and then contoured on a lathe to the specifications of the US Marine Corps for the M40 barrel.

The barrel blank comes crowned and finished with a rough exterior to hold a Duracoat or similar black finish. We have some close-up pics to show you the surface. There is a scoring of sorts. I am sure that the barrel smiths have a name for it.

Finally, the Schneider barrels are individually hand-lapped to provide the desired surface finish and rifled bore uniformity for the full length of the finished barrel.

Charlie's also stocks a similar barrel from Douglas, which is a ready to use drop in pre-fit barrel, chambered in 7.62 NATO and ready to install into a Remington 700 receiver. If you are interested in a near-clone M40 barrel, ready for use, look here: M40 pre-fit barrel from Douglas Barrels