This is a turn-key shop service to receive your DD Mk12 upper receiver, and tune the profile of the barrel and add a custom designed Allen collar and the standard AEM brake, to successful fit an Ops, Inc. #12 style suppressor, like the Allen Engineering AEM5.

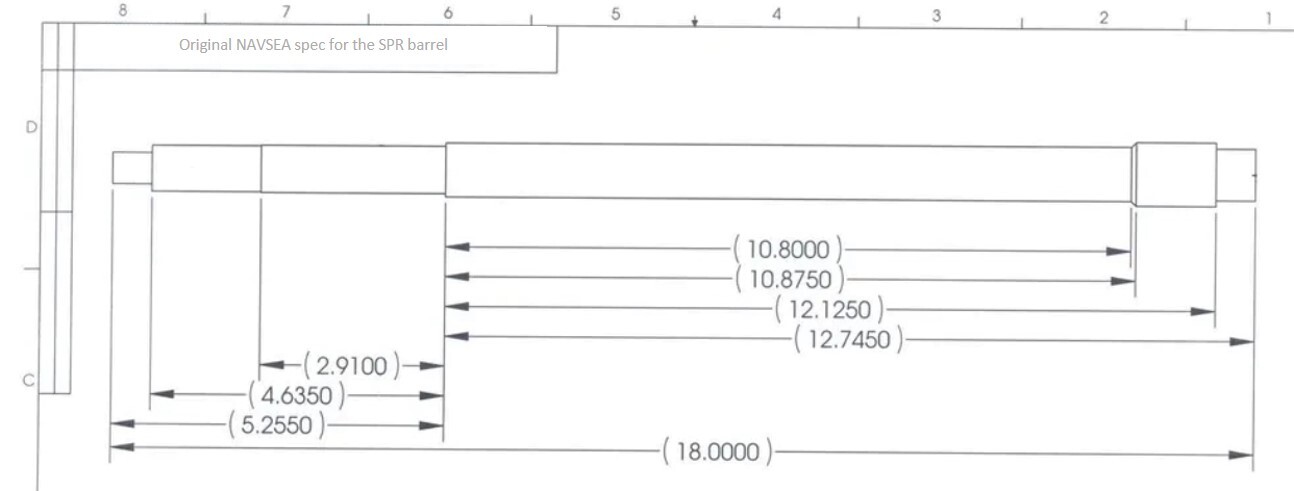

The Mk12 rifle uses a very specific 18" SPR profile, and Allen Engineering has designed their long and short SPR collars and brake to fit the specific profile, which they actually make publicly available. During the design of the Mk12 SPR in 2000, there was a published barrel profile used by the US Navy for their program. However, before the program began, NSWC Crane, and the suppliers of the Mk12 program, make some modifications to the design before the suppliers manufactured the upper receiver groups. One of the late changes was in the actual barrel profile. Evidently, a number of manufacturers have seized on the early schematics of the barrel, and have incorrectly profiled the barrel.

The SPR design calls for a step, or a shelf to start at a certain distance from the muzzle. It is on this step that the collar stops and is secured. The original design called for the shelf to be located 2.35" from the muzzle, but the Ops, Inc. design for the suppressor called for 2.40". Many commercial barrel makers today, including Daniel Defense, use the NAVSEA pre-production design, and not the Ops, Inc. design, which Allen Engineering uses to this day in the specifications for their suppressor. Either design will allow the installation of the SPR collar and brake, but only the Ops, Inc design will correctly secure the AEM5 suppressor.

In fact, we measured a good number of commercial barrels and found that most were profiled to the original design, making each quite incompatible with the AEM5 suppressor.

For the DD barrels we have measured, the distance to the step is roughly 0.06" too close to the muzzle, which would be consistent with the original design. What this means is, that with the proper spacer and timing shims, the AEM5, when installed, does not get the proper rotations to secure the suppressor. Ron Allen, from Allen Engineering, has found that the majority of baffle strikes (damage to his suppressors) has occurred with barrels which are incorrectly profiled, or the use of knock-off collars or brakes. What we are seeing, at Charlie's, is that Daniel Defense barrels will get around 4 rotations, while the correct standard is between 6-3/4 and 9 rotations. For barrels that are SPR profiled, we normally see the rotations to be in the middle of that range, 7-/1/2 to 8-1/4, for example.

The following diagram shows the correct profile needed:

Well, if you have a Daniel Defense barrel, you have a few choices: One choice is buy the Allen Engineering SPR hardware and not run a suppressor. I suppose the first real choice is do nothing, as DD has not included the Allen hardware, and has a DD flash hider. But, if you want to bring your DD rifle into more of a clone correct look, having the AEM collar and brake is a nice choice. If you want to use the AEM5 suppressor, you could send your barrel to a barrel smith and ask them to profile your barrel to the SPR format, or perhaps you are handy and have a machine shop and a lathe, and you can do it yourself. These are all possible solutions.

Now, what we are offering at Charlie's is a hassle-free turn-key solution. We will make adjustments to your barrel and we will install a specific collar, which is made by Allen Engineering for us for this retro-fit. We will email you a mailing label, and you can send us your entire upper receiver group, and we will make all the adjustments, install the collar, install the brake and properly time it, and then test fit an actual AEM5 suppressor and run a bore guide down your barrel to make sure the suppressor fits correctly. I suppose it is possible that a barrel fails the test, but that has not happened yet, and with DD's cold hammer forged process, their barrel bores are very uniform. We will then ship your upper receiver back to you, ready to use.

Our service includes the shop service, the actual Allen Engineering collar and break, and shipping to us. You can choose standard free shipping back to you as well. We are not going to change your gas block. You can ship us just the barrel, if you wish, or do not hassle with that, and just remove the BCG and charging handle and find a box to use.

If you have any questions, contact our sales staff at sales@charliescustomclones.com .

Note: if you have not yet purchased a Mk12 upper receiver, Charlie's also sells the Mk12 upper with the Allen hardware installed here: DD Mk12 upper receiver group with AEM collar and brake